|

by

David Barron

For better than 20

years, I have built or helped build several model railroad electrical control

panels. At first, these ended up very simple; later ones ended up

somewhat more complicated. During my

latest venture, I wanted to install something with a little more zing, and yet

foolproof, simple, and inexpensive. The

thought of having illuminated turnout position indicators allows you to tell at

a glance if you are lined up or not. The

idea of having this illumination, rather than toggle switch position, appeals to

everyone.

Several commercial

illuminated switches have been offered, which at times were mechanical

nightmares or complicated wiring nests. If

anything ever went wrong, as it always eventually does, simplicity is a must. Light emitting diodes (LEDS) seem to be the answer. The following circuit will work with any system that requires a constant

power supply to the switch machine (i.e., Tortoise by Circuitron -- not solenoid

or momentary contact circuits).

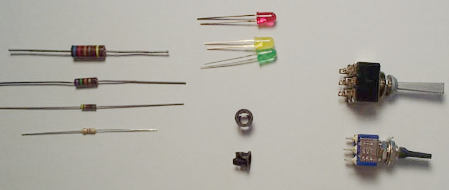

Figure 1 shows the

minimum components required for this circuit; for each indication required they

include 1 1K Watt Resistor and 2 colored LEDS, the colors are your

choice. Optional pairs would include

1 plastic LED holder per LED in the control panel. All of these parts are readily available at all electronics

stores, including Radio Shack, or your local hobby shop by Miniatronics. Miniatronics has an 18 pieces set of red, yellow, and green LEDS with

resistors all in a single package (Model 12-050-18) for about $7.50. That is enough to do at least 5 position indicators and have some parts

left over.

Figure

1. Components for circuit.

My requirement was to

color code the LEDS so that Green would indicate the switch was set for

the main line operations and Yellow would indicate the switch was set for

the siding. A quick glance at the control panel was all that was needed

to tell if all switches were properly aligned prior to main line or Green

Light operations.

Here's a quick note

or explanation as to the functions of these two simple components for those who

are unfamiliar with them. Resistors

come in many sizes and shapes but they all do the same basic thing, they limit

current. They operate like a funnel and only allow so much current to

flow through at a time. They are

color coded with different bands of color to indicate their different

restricting values. You can consult

any electronic book for your favorite memory code jogger, or visit http://www.dannyg.com/examples/res2/resistor.htm

for a Resistor Calculator.

Diodes also come in many sizes and shapes. They also come under different names depending on their

function, the ones that we want are known as Light-Emitting Diodes, LEDS.

These come in three basic colors: Red, Green, and Yellow.

An LED works, or lights, when a current passes through it in one

direction only. That is the way a

diode works, it only allows current to pass thorough it in one direction and not

the other way. Kind of like a one

way check valve. By positioning the

LED the way we want we can control its function much like a one way

electrical valve and see the valve position.

The reason we are

using a resistor in this circuit is that we are using the 12 volt DC poser

supply common with most power packs. We

want to drop the power down to a value that will not damage the LEDS.

The LEDS are used in opposing positions so that as we change the current

polarity, by throwing the toggle, we reverse the current through the LEDS, so it

cannot go through the lighted LED anymore but it now goes through the LED not

previously illuminated.

Although there are

exceptions to every rule, I have never found an LED that didn't have one long

leg and one short leg. The proper

names are the cathode lead and the anode lead, but I'll refer to them as the

short and long legs. There are a

few things that you must remember in order to correctly get this circuit

working. First NEVER attach the LED directly to power without the

dropping resistor or it will go pop and like a match it won't work a

second time. The second thing is that these LEDS must operate opposite of

each other or they will both light together or go out together, not what we are

looking for. Lastly, use heat

sparingly as excess heat when soldering can damage the components.

If you are using a

double pole, double throw (DPDT) toggle switch, wired up as Linn Westcott

indicates in his book, How to Wire Your Model Railroad, to reverse

current, then this circuit can easily be added to your existing system.

Figure 3 shows how the back of the DPDT Toggle should be wired.

Now, Let's get

started. Figure 2 shows the basic

circuit that we are about to put together.

First, locate where you can't the LEDS located on your control panel.

I put mine next to the respective toggle switches in a vertical line.

This allows me to take a quick glance down at them to make sure

everything is lined up. After

drilling the appropriate holes in your control panel, (I found that a Masonite

hard board is perfect for the job), you can either glue the LEDS directly in

place or use the special plastic snap clips to mount them in.

I like the plastic clips in that it leaves a nice finished black ring

around the LEDS when viewed from the top and it makes them easy to replace

should you have to. Now, solder

either end of the 1K Watt Resistor lead to point A on the toggle and

the other end the short leg on one LED and long leg on the other

LED. Next, solder one end of the wire

to point B on the toggle and the other end to the remaining two LED legs.

Turn your switch machine power on and you should have one LED lit and the

other one off. Flip the Toggle and

the lit LEDS should switch illuminated positions.

If the LEDS both go on or off, at the same time when you flip the toggle

switch, you simply have one in backwards. Unsolder

one and turn it around and test it again.

Figure

2. Double pole double throw toggle switch.

What's

the advantage of this system over the other systems?

It saves a lot of time and excess wiring from the toggle to the switch

machine. For those individuals who will say this system doesn't show

the position of the switch machine or points, I answer by simply saying, on a

correctly wired and operating system, this is easier to understand and the

control panel indication end results are the same. In reality, it is a visual indication of the switch position

rather than turnout position, but the switch controls the turnout, so all is

good. The only time the lights and

the turnout would be out of sync would be during a malfunction.

Other than that, this is a positive, simple, and inexpensive turnout

position indicator.

Click

ARTICLES to read other techniques for model railroading. |