|

HOME

Cedar Shingles

Figures

Forest Turf

Logcar Kits

Model Fences

Natural Stumps

Plating Service

Power Lines

Sawmill Wood

Scale Glass

Sound Cams

Weathering

Shipping

Product List

Brass Sales

RR Gallery

RR Articles

RR Links |

|

by

David Barron

When I was

growing up in the upper Midwest, I remember very clearly visiting my

grandfather's farm in Grays Lake, Illinois. I was told prior to

his death that he was not only a farmer but also a J. I. Case Equipment

dealer. He had a very large three-story barn where he kept his tractors

and equipment. His business was known as Barron Implement.

As I grew up, I remember the unusual vertical rods on top of his barn

and other wooden yard structures. One day I asked my father what

they were for, and he told me the following story.

First, he

said that when he was a young boy, the glass balls on the rods were

targets for his .22 caliber rifle -- until he got caught! My

father emphasized that his father got rather angry for shooting the

balls off his lightning rods! Gee, I wonder why? He then told me that

the rods were part of a lightning protection system which was installed

on the buildings to protect them from lightning damage, mainly fire.

When I asked about the glass balls, he said that they were indicators

that a lightning rod had been hit by lightning. The rod would

super heat and cause the glass ball to shatter, thus becoming an

indicator of a strike and to check the system for damage. These colored

glass balls were

not merely ornamental, but a vital element in the protection system.

These systems had always intrigued me and in my early modeling years, I

installed them on the roofs of my scale structures. In some NMRA contests

and in a few published pictures, I have seen these rods installed on

other models, some of them properly and others improperly. In an effort to

get the best information available about lightning rods, I contacted one

of the leaders in the field, Mr. Douglas J. Franklin, Vice President

(and descendent of Benjamin Franklin), Thompson Lightning Protection,

Inc., of St. Paul, Minnesota. Mr. Franklin provided all the

diagrams from his catalog. I also consulted my local Internet

service and did a search for more information.

First of all,

let's discuss a little about lightning. Lightning is a short lived,

high current electrical discharge in the atmosphere, which can occur

between clouds, cloud to air, and in its most destructive mode, cloud to

ground. Lightning is responsible for millions of dollars worth of

damage every year to both forests and civilized areas, just in the

United States! It is further responsible for between 200 to 500

deaths per year, just in the United States. Basically what happens

is that buildups of negatively charged free electrons exist in the

atmosphere. Their invisible release along a specific path, known

as stepped leaders, occurs when a discharge takes place near a cloud

base. The negatively charged step leader works downward to a point

approximately 150 feet or less above the ground where another stepped

leader from the ground, a building, tree, or other protruding objects,

reaches up to meet it. At that point, when the two leaders meet,

the visible lightning is produced. Several strokes of lightning

can occur along this path until the charge center as the base of the

cloud has dissipated. The thunder that we hear is really a shock

wave caused from the intense and explosive heating and expansion of the

air along the discharge path.

During the

1700's, Benjamin Franklin was doing his famous "fly the kite in the

storm experiments." By 1749, he had suggested the use of

lightning protection equipment in the form of metal rods for building

and other structures. Ben's theory was that if a metal rod was

placed at the highest point on the structure and grounded by a low

resistance cable, lightning would strike the rod and pass harmlessly

along the system and into the ground. Ben went on to say that a

rod's area of protection was equal to a cone-shaped area with its base

equal to the height of the rod itself. |

|

| Well,

now that we know a little about lightning, how do we model a protection

system on our scale buildings?

Several different applications

can be used -- from just cutting off the head of a straight pin

and sticking it into the apex of roofs to a full fledged model of a

lightning protection system. I suggest using a K& S .020 solid

brass rod and super gluing either Clover House #39 or

Sierra Scale

Models #120 white or colored insulators (glass beads) midway on the rod

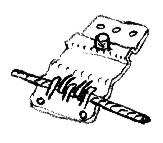

or air terminal. Figure 1 shows a copper or aluminum class 1 air

terminal with threaded mounting pin. This will provide

several very realistic rods for less than a penny. |

Figure

1. Rod w/insulator. |

|

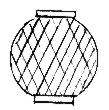

| Several

different rod designs are offered from the Thompson Lightning

Protection, Inc. All of these designs, some as old as the turn of

the century, have some form of grounding cable attachment points.

A sample is shown in Figure 2. Some designs are for flat

structures, some for peaked roofs; others are for stacks and chimneys.

Grounding cables can be simulated using waxed thread, wire, or

monofilament line. Connect all rods together and continue down to

and attach to a copper ground rod. The standard grounding rod is

anywhere from 1/2 inch to 3/4 inch in diameter and up to twelve feet

long. I suggest using the K&S brass rod for this. |

Figure 2.

Mounting base. |

|

|

| The

glass balls were used exclusively up to the 1940's. After that,

plastic balls became common, and few manufacturers continued producing

the glass balls. Some of the balls were hand blown, as the

Polar Star (Figure 3), which dates back to 1916. They were

five inches in diameter and fit a 5/8" lightning rod. They came

in transparent amber, opaque blue, transparent green, transparent red,

and opaque white. |

Figure

3. Polar star. |

|

|

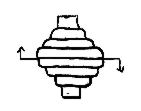

| Today,

an increased demand for glass balls has resulted in complete new

designs. Thompson offers these new glass products in transparent

amber, transparent blue, transparent dark green, transparent ruby red,

and opaque white. Now, the balls come in two hemispheres and are

plastic, which are put

together face to face on the rods. The two halves can be of

different colors, resulting in an infinite number of color

possibilities. The plastic balls are set together, (Figure 4 illustrates a skyline plastic ball with ribbed

style). |

Figure

4.Skyline plastic balls. |

|

|

| They

are made of a tough weather-resistant and fade-resistant styrene plastic

and are almost indestructible -- purely decoration. They come in

many colors also -- sky-blue, transparent red, golden yellow, silver

gray, transparent green, and snow-white. The

glass balls were held in place on the lightning rod with a ball support

ring, plastic balls fitting tightly over the rods. That ring is really

nothing more than a thick metal washer device, with setscrews to tighten

them down on the rod. Then, a special hold down washer is used to

prevent the balls from blowing off the lightning rods. A note

should be made that at no time were holes drilled in the rods or pins

installed for this application because heating and cooling could cause

the pins to become loose. Then, they would fall out causing the

indicator balls to fall and break. A good simulation of these

support rings and hold down washers can be made by cutting a short

section of insulation from an insulate wire and putting it above and

below the glass bead.

By now if you

have followed this article and studied the drawings, you have become an

"expert" in the lightning and model lightning protection

field. Since you know the dangers of not protecting your structures,

you should either add these items or show some structures with lightning

damage! You could start a new industry on your pike for selling

lightning protection equipment or have some men either repairing or

installing a new system on one of your buildings.

Source

|

Click

ARTICLES to read other techniques for model railroading. |

|

|